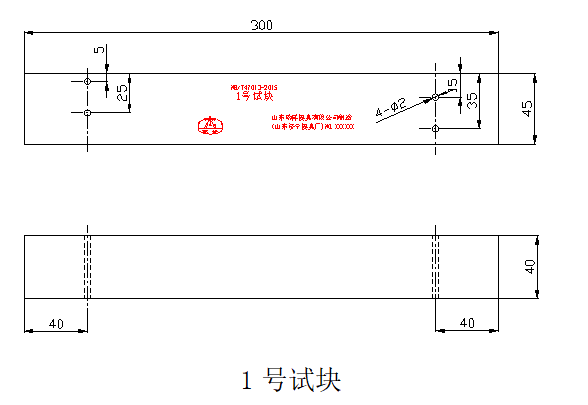

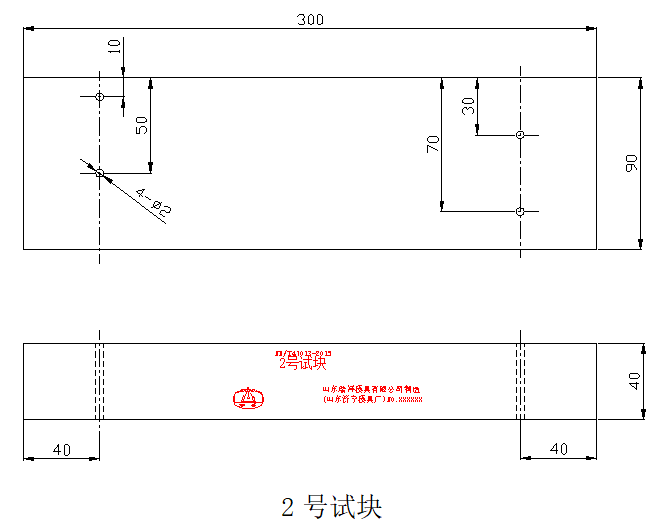

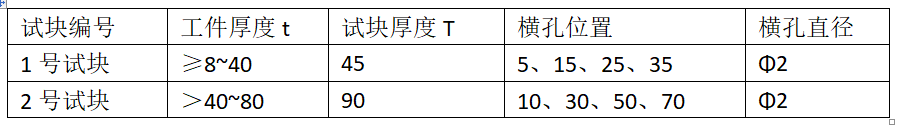

Test block No. 1 and test block No. 2 are designed according to NB47013 standard and the requirements of quality classification of ultrasonic testing method for aluminum and aluminum alloy and titanium pressure equipment butt joints. They are suitable for ultrasonic testing of aluminum and aluminum alloy and titanium pressure equipment butt joints with thickness greater than or equal to 8mm ~ 80mm. The design content of the test block is shown in the following table:

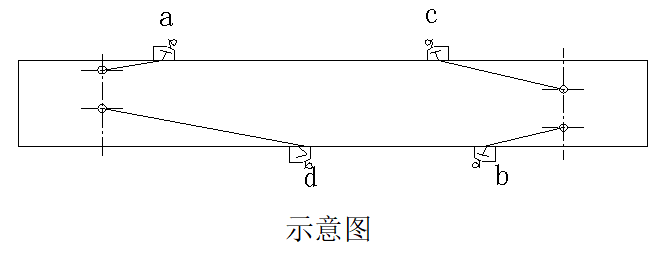

Test method: Select the diagonal probe that has been verified and place it at the position a in the diagram. Move the probe back and forth so that the direct sound beam can get the maximum reflection echo on the φ2mm cross through hole. Adjust the echo amplitude to 80% of the height of the full screen, record the dB value at this time, which is the first point. The probe is placed at position b in the diagram, and the probe is moved forward and backward so that the direct sound beam can get the maximum reflection echo on the φ2mm cross through hole. Adjust the echo amplitude to 80% of the height of the full screen, record the dB value at this time, which is the second point. The probe is placed at position c in the diagram, and the probe is moved forward and backward so that the direct sound beam can get the maximum reflection echo on the φ2mm cross through hole. Adjust the echo amplitude to 80% of the height of the full screen, record the dB value at this time, which is the third point. The probe is placed at position d in the diagram, and the probe is moved back and forth so that the direct sound beam can get the maximum reflection echo on the φ2mm cross through hole. Adjust the echo amplitude to 80% of the height of the full screen, record the dB value at this time, which is the fourth point. Connecting the above points into a curve is the base line specified in the standard.